Optimal Timing for Pervious Concrete Work

Spring offers moderate temperatures and ideal conditions for installing pervious concrete, ensuring proper curing and adhesion.

Summer's warm weather facilitates repairs, but precautions should be taken to avoid rapid drying or excessive heat.

Fall provides cooler temperatures and less rainfall, making it suitable for both installation and repairs before winter.

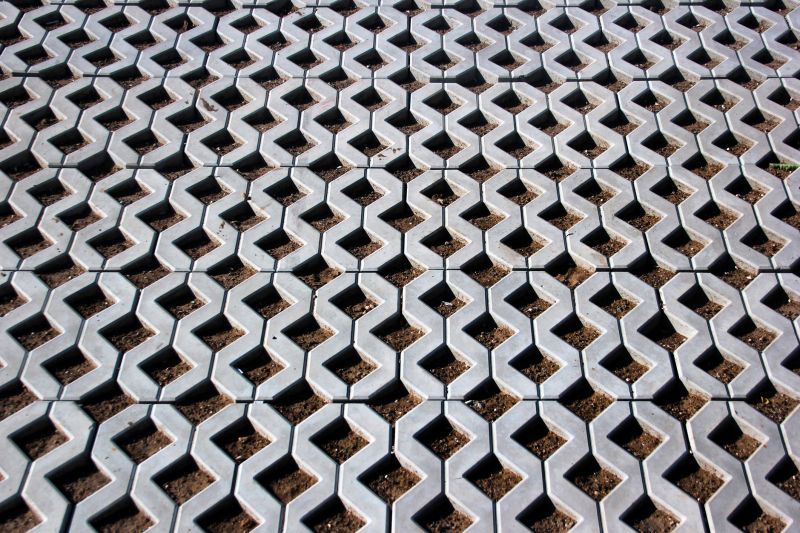

Ways to make Pervious Concrete Installation And Repairs work in tight or awkward layouts.

Popular materials for Pervious Concrete Installation And Repairs and why they hold up over time.

Simple add-ons that improve Pervious Concrete Installation And Repairs without blowing the budget.

High-end options that actually feel worth it for Pervious Concrete Installation And Repairs.

Finishes and colors that play nicely with Pervious Concrete Installation And Repairs.

Pervious concrete installation and repairs are most effective when performed under specific seasonal conditions. Temperature, humidity, and rainfall significantly influence the quality and longevity of the surface. Optimal conditions typically include moderate temperatures, low to moderate humidity, and minimal precipitation. Installing or repairing during these periods helps ensure proper curing, reduces the risk of cracking, and extends the lifespan of the pavement. Proper timing can also minimize disruptions and reduce costs associated with weather-related delays.

Statistics indicate that scheduling pervious concrete work during spring and fall can improve durability by up to 15%. Warm, dry conditions during summer are suitable for repairs, provided measures are taken to prevent rapid evaporation. Conversely, winter is generally unsuitable due to freezing temperatures, which can impair setting and curing processes. Therefore, understanding seasonal weather patterns and planning accordingly can lead to better results and longer-lasting installations.

Spring's mild weather supports optimal curing and adhesion for new installations and repairs.

Warm weather allows effective repairs, but precautions against rapid drying are necessary.

Fall is ideal for completing installations before winter, with cooler temperatures aiding curing.

Cold temperatures and precipitation hinder installation and repair efforts, risking surface integrity.

Little measurements that prevent headaches on Pervious Concrete Installation And Repairs day.

A 60-second routine that keeps Pervious Concrete Installation And Repairs looking new.

A frequent mistake in Pervious Concrete Installation And Repairs and how to dodge it.

Small tweaks to make Pervious Concrete Installation And Repairs safer and easier to use.

| Season | Best Practices |

|---|---|

| Spring | Install during moderate temperatures, avoid heavy rain, ensure proper curing conditions. |

| Summer | Perform repairs early in the day, protect surface from rapid drying, monitor temperature. |

| Fall | Complete work before temperature drops significantly, prepare for winter conditions. |

| Winter | Generally not recommended due to freezing temperatures and moisture issues. |

Scheduling during optimal seasons enhances durability, reduces repair frequency, and extends service life.

Proper planning ensures work is completed under suitable conditions, reducing risks and costs.

Choosing the right time for pervious concrete installation and repairs is essential for achieving optimal results. Proper timing minimizes the risk of surface damage, cracking, and reduced permeability. It also ensures the longevity and performance of the pavement, making it a critical factor in project planning. Weather forecasts and seasonal trends should be considered to align work schedules with favorable conditions, ultimately leading to better durability and lower maintenance costs.

Ideal for new installations due to stable weather and moderate temperatures.

Suitable with proper precautions against rapid evaporation and heat stress.

Supports completion before cold weather sets in, ensuring proper curing.

Generally avoided due to freezing temperatures that impair setting and curing.

The short, realistic tool list for quality Pervious Concrete Installation And Repairs.

Rough timing from prep to clean-up for Pervious Concrete Installation And Repairs.

Quick checks and paperwork to keep after Pervious Concrete Installation And Repairs.

Examples that show the impact a good Pervious Concrete Installation And Repairs can make.

Interested parties are encouraged to contact for further details or to schedule installation and repairs during the most suitable seasons. Proper timing can significantly influence the success and durability of pervious concrete surfaces, ensuring they perform effectively over time.